DIY Bed Building & DIY Slatted Frame with Mattress Guide

Is there a stationary place where we spend more time than in bed? Hardly. Over a lifetime, the hours quickly add up to around 25 years – an astonishing number. All the more important to engage deeply with the topic of sleep environment. Because not only the time spent there is crucial – the effects on the body can also be significant, both positive and negative.

The Mattress – The Heart of the Bed

Let's start with the essentials: the mattress. A high-quality mattress, well maintained, can last up to 15 years. Therefore: a clear recommendation to try it out – preferably in a real specialty store. If no questions about your preferred sleeping position are asked there or if it is not addressed which body areas should be supported or relieved based on your figure, you are probably at the wrong place. A good mattress is recognized by its even support of the body. If you feel pressure on your shoulders when lying down or your pelvis sinks, these are clear signs that it is time for a new mattress.

The Slatted Frame – Useful or Overrated?

On the subject of slatted frames, I like to quote Stiftung Warentest: "It is not proven that an elastic slatted frame brings advantages." I also never quite understood why a curved wooden construction is placed under a mattress, causing it not to lie flat. Especially with wide beds and conventional slatted frames, this can lead to problems – for example with weight differences between two people. What must not be neglected, however, is ventilation. This is essential – both to prevent mold and for the longevity of the mattress.

DIY Slatted Frame: Simple, Stable, Well Ventilated

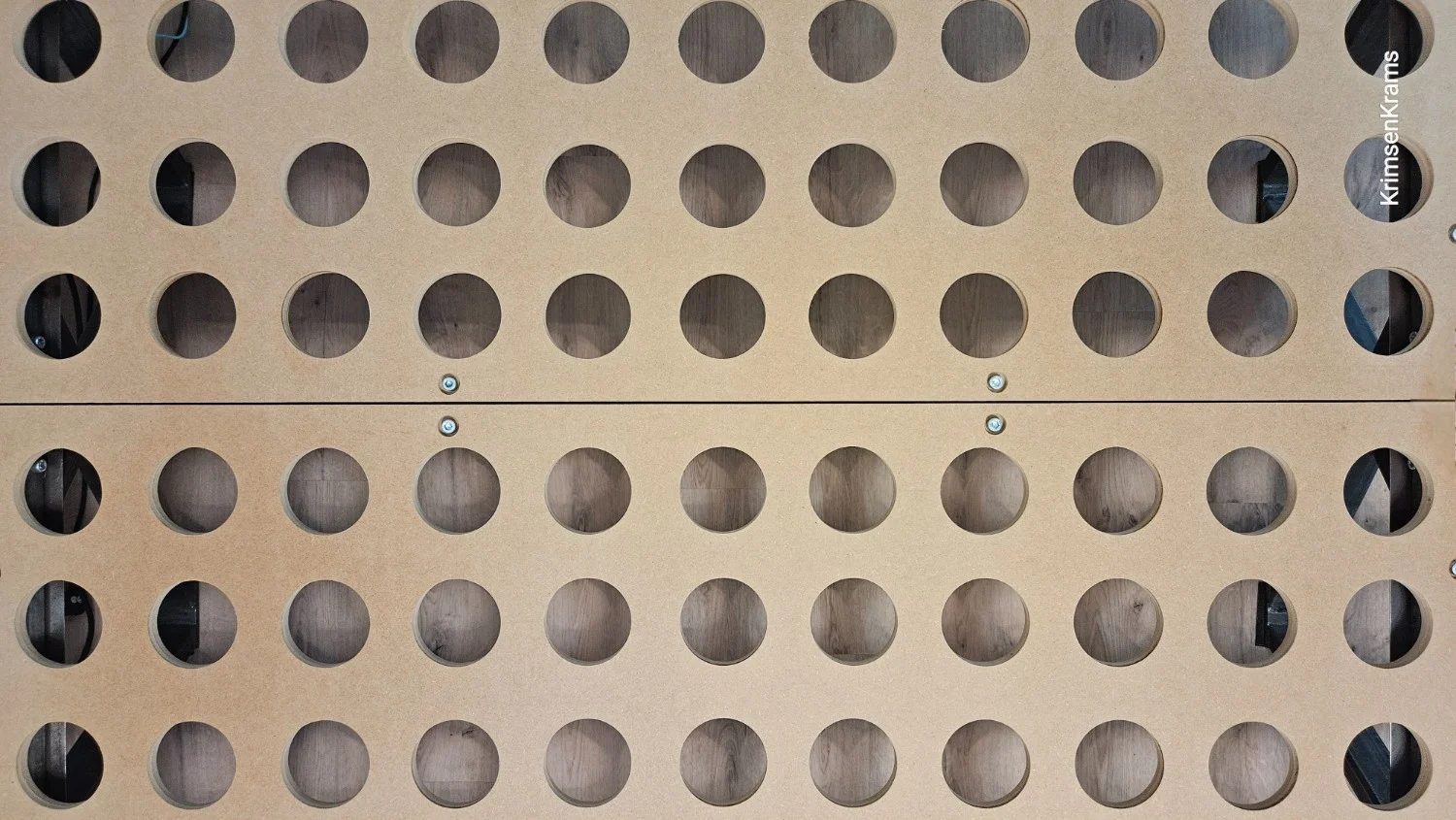

A practical approach is the use of two MDF boards measuring 140 × 200 cm, each equipped with round ventilation holes (Ø 10 cm), totaling 104 pieces. This corresponds to about 30% of the total area – an acceptable value, even if conventional slatted frames usually ventilate a bit better. The stable surface prevents local bulges and reduces mattress slipping. For two people with a significant weight difference, the behavior of the lying surface can be tested individually.

The DIY Bed Construction – Steel, Simple and Solid

A stable bed frame serves not only an aesthetic but above all a functional purpose. The described construction is entirely based on steel parts, with welded joints and few screw connections. There are different opinions on the choice of material. Some view metal constructions critically, for example due to potential antenna effects of electromagnetic fields. In theory, this is possible; whether this is practically relevant remains to be individually assessed. Personal opinion: No difference in sleeping comfort is noticeable.

Assembly of the DIY Bed Frame

The construction consists of five main parts:

- Two foot frames

- Left and right side frames

- Center rail

The center rail could also be permanently connected to the frame – its size still allows easy transport through doors. The frame is designed for a 140 cm wide mattress. This size is considered sufficient for many couples and promotes closeness in shared sleep.

The Feet

The feet consist of 7 × 3 cm steel tubes with a 5 mm wall thickness – an extremely robust dimension. The distance between the feet is 70 cm, providing sufficient stability. A smaller distance could lead to a tipping moment, for example when sitting on the side edge of the bed. Countermeasures would be additional weights or a larger foot spacing. A stiffening angle in the middle of the feet, screwed to the frame, ensures stability in the longitudinal direction. A stainless steel plate with holes is welded to the feet – these allow connection to the upper frame using M10 screws.

The Upper Frame

The middle part of the frame consists of a 10 × 4 cm steel tube, at whose ends a steel block is welded. These are inserted and screwed into the side frame tubes (4 × 4 cm). For attaching the slatted frame, there are ten threaded holes per side. The previously described MDF boards are mounted there. Important: The screw heads should be countersunk into the boards to ensure an even surface.

Conclusion

The three central requirements for a durable and comfortable bed are:

- A mattress that supports the individual body shape

- Permanent ventilation of the mattress

- A solid, tip-proof bed frame

Whether steel or wood, bought or self-built – what matters is that the bed meets personal requirements and convinces both ergonomically and functionally.